Industrial Coffee Grinder: Important for Cafés and Bistros

Industrial Coffee Grinder: Important for Cafés and Bistros

Blog Article

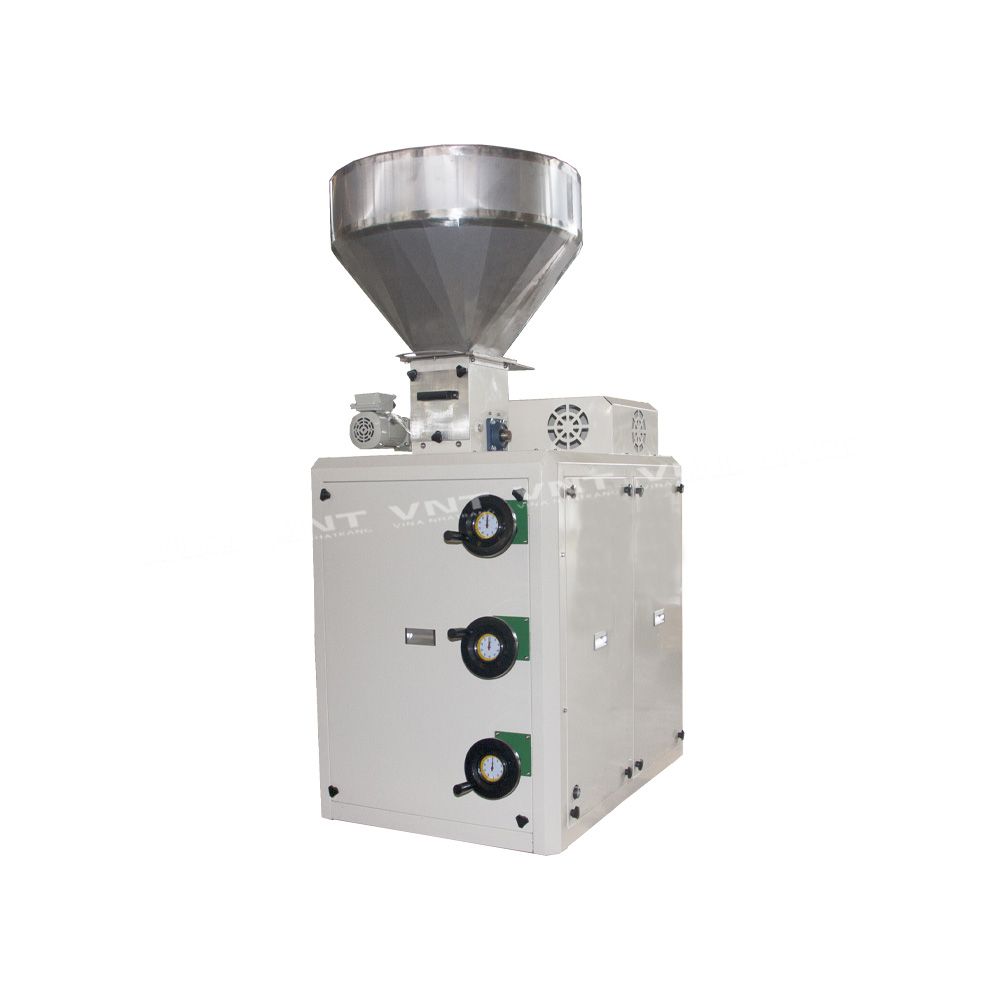

Industrial Coffee Mill Overview: Boost Performance and Quality

In the affordable landscape of coffee production, picking the appropriate commercial coffee grinder plays a crucial function in improving both effectiveness and product top quality. Comprehending the subtleties of various mill kinds and crucial features-- such as adjustable work settings and durable building-- can substantially affect the final taste profile of the coffee.

Comprehending Mill Kinds

When picking an industrial coffee mill, recognizing the numerous types available is critical for optimizing both taste extraction and functional effectiveness. Both primary kinds of mills are blade mills and burr mills. Blade mills use sharp blades that slice coffee beans into inconsistent sizes, causing unequal extraction and possibly undesirable flavors. While blade grinders are frequently a lot more appropriate and budget-friendly for small operations, they are typically not suggested for commercial usage.

Ultimately, selecting the right sort of grinder is essential to preserving top quality and efficiency in coffee manufacturing, making it essential for organizations to invest in high-grade burr mills for ideal outcomes.

Key Functions to Consider

Choosing an industrial coffee grinder calls for mindful consideration of several key features that can considerably influence both efficiency and the overall coffee experience. One of the key aspects to assess is the grinding system. Burr grinders are usually favored over blade grinders, as they supply a regular work size, which is critical for ideal extraction and flavor.

Another vital feature is the grinder's capability. Depending upon the volume of coffee you need to process, choose a model that can manage your requirements without sacrificing speed or top quality. Furthermore, think about the work setups offered. A versatile grinder with several setups enables you to customize the grind dimension to different developing approaches, enhancing the coffee's flavor account.

The building and construction product also contributes in durability and maintenance. Stainless-steel components usually use durability and are much easier to cleanse, which is essential for maintaining hygiene criteria. Assess the mill's sound degree, specifically in a busy café or production atmosphere, where extreme noise can be disruptive. Buying a grinder that balances these attributes can substantially boost both operational effectiveness and the high quality of the coffee offered.

Optimizing Grinding Refine

To attain the very best lead to coffee prep work, optimizing the grinding process is crucial. The work size significantly influences extraction, flavor, and general high quality of the brewed coffee. Various developing methods require details grind dimensions; for example, coffee demands a fine grind, while French press requires a crude structure. Understanding the partnership in between work size and brewing approach is the initial action in optimization.

Additionally, monitoring the grinding rate can optimize the process. Slower grinding commonly generates much less warm, protecting delicate flavors and fragrances. Alternatively, quicker grinding might create too much warm, adversely influencing the coffee's high quality.

Maintenance and Care Tips

Appropriate upkeep and care of industrial coffee grinders are vital for ensuring optimum performance and longevity. Regular cleaning is the foundation of maintenance; deposit build-up can affect flavor and grinding performance. It is a good idea to cleanse the mill after each use, cleaning down the exterior and removing any kind of coffee grounds from the burrs.

Additionally, inspect the grinding burrs for deterioration. click here now Dull burrs can endanger work consistency, so they must be replaced as necessary. Industrial Coffee Grinder. Regularly calibrating the mill is likewise essential, as this maintains the desired grind dimension for numerous brewing methods

Lubrication of moving components ought to be done according to the producer's specs, as this lowers rubbing and lengthens the life of the devices. It is important to use food-grade lubes to make certain safety and conformity with health laws.

Last but not least, maintain the grinder in a secure and dry atmosphere to avoid corrosion and corrosion. By adhering to these maintenance and care suggestions, operators can boost the performance of their industrial coffee grinders while making sure high-grade result and extended functional life.

Return on Investment Evaluation

Assessing the return on financial investment (ROI) for industrial coffee mills is critical for businesses looking for to enhance their coffee production capacities. A detailed ROI analysis aids identify the monetary viability of investing in top notch mills, allowing organizations to consider the initial prices versus possible gains.

Assess the acquisition cost of the grinder, consisting of installment and any type of necessary adjustments to existing infrastructure. High-performance grinders typically lead to lowered grinding time and raised throughput, which can dramatically enhance performance.

Additionally, take into consideration the impact on product high quality. Industrial Coffee Grinder. Superior grinders yield a more constant grind dimension, which can improve taste accounts and customer satisfaction, eventually driving sales. By enhancing the quality of the end product, businesses can justify greater pricing, leading to raised profits

Verdict

In summary, an industrial coffee grinder plays a this page critical function in improving both effectiveness and item quality within coffee manufacturing. Eventually, the tactical financial investment in a trusted grinder adds dramatically to enhanced revenue and competition in the coffee sector.

In Read Full Article the competitive landscape of coffee manufacturing, choosing the right industrial coffee grinder plays a pivotal function in enhancing both effectiveness and item high quality. The two primary kinds of grinders are blade mills and burr mills. Within the burr mill classification, there are flat burr mills and conelike burr mills, each with its advantages. Burr grinders are generally chosen over blade mills, as they offer a constant work dimension, which is essential for optimum removal and flavor.

In recap, an industrial coffee mill plays a critical duty in boosting both performance and item high quality within coffee production.

Report this page